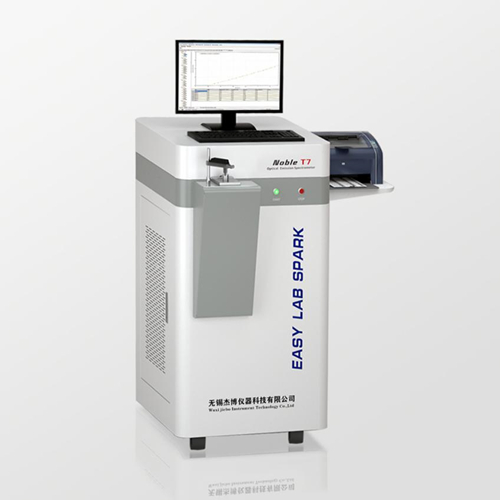

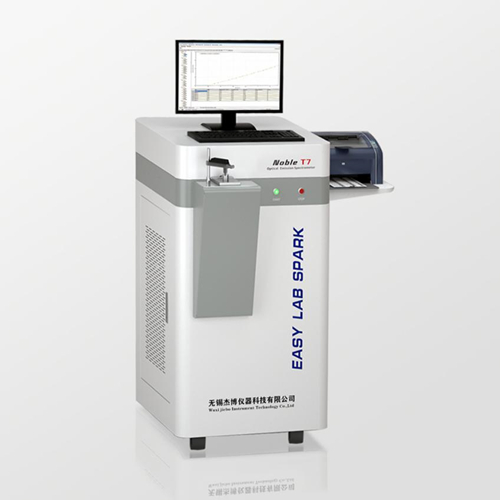

Installation Conditions Of Optical Emission Spectrometer In Laboratory

When purchasing optical emission spectrometers, preparations for laboratory installation conditions and requirements are generally prepared. When the installation conditions are met, the instrument can be smoothly installed and the normal operation of the instrument can be guaranteed. The following editors will sort out what are the installation conditions and requirements of the direct reading spectrometer laboratory.

1. Environmental requirements for optical emission spectrometer laboratory room:

The size of the room should be moderate, and the area should be larger than 16 square meters. It is too small, looks crowded, too large, and the room temperature is not easy to control. In order to prevent dust, it is better to use double doors and windows in the laboratory. The laboratory should have the necessary width to allow the instrument to enter and exit smoothly. It should also have sufficient space for movement and a safe passage to avoid accidents.

2. Humidity and temperature requirements:

The laboratory should be equipped with a corresponding humidity detection device (such as a thermo-hygrometer) to read and monitor the temperature and humidity of the laboratory at any time. In order to ensure the stability of the temperature and humidity in the laboratory, air conditioning must be provided. The ambient temperature in the laboratory is generally 15 ~ 25 ° C, and the humidity is controlled at 45% -75%. If the instrument is kept working normally, the temperature of the laboratory should not change too much. Generally, the hourly change does not exceed 2 ° C, the daily temperature does not exceed 10 ° C, and the optimal humidity is 70%. Within this temperature and humidity range, the stability and data quality of the instrument can be ensured.

3. Earthquake-proof requirements:

In order to obtain good shock resistance, the laboratory floor is required to be more than 50㎝ above the ground surface, and it should be selected on the short floor (1-3 floors) as far as possible, without obvious vibration, and the impact resistance is 10 gravity accelerations.

4. Anti-interference requirements:

The laboratory should be far away from large equipment (such as intermediate frequency furnaces, transformers and other high frequency generating devices) and places with unstable electromagnetic interference in the power grid. The house requires anti-electromagnetic interference, and the RF signal attenuation is greater than 103dB.

5. Dust requirements:

The indoor dust requirement is less than 500 particles per kiloliter. Keep away from chemically corrosive gases. The instrument should be kept away from direct sunlight and away from the vent (cold air vent or hot air vent).

6.Configuration requirements of instrument table:

In order to facilitate the operation of the instrument, the user needs to be equipped with a computer workbench (which can put a computer and a printer) and 1-2 mobile seats. The computer workbench must be equipped with a power socket board with a ground wire jack.

7. Power requirements:

Total power requirements: single-phase voltage 220VAC ± 10%, current greater than 20A, 50Hz ± 0.5%, in order to make the spectrometer safe for long-term use, a single-phase 220VAC power 1-3KW magnetically saturated stabilized power supply is required Requires stable quality and response time less than 10ms.

8. Argon requirements:

The purity of the argon gas supply must be above 99.999%. The purity of the gas will directly affect the analysis quality of the sample. If the gas contains more impurities, the stability of the excitation will be greatly reduced, and the parallelism and reproducibility of the measurement will be poor. Therefore, users are strongly recommended to use high-purity argon, otherwise it will cause unnecessary trouble to the analysis. If it is difficult for users to purchase high-purity argon, they must be equipped with an argon purifier.

9. Power failure protection requirements:

In order to prevent a sudden power outage in the power grid, an incoming call will occur immediately, which will have an impact on the instrument. Therefore, it is required to install a magnetic starter with a current of not less than 20A between the main power supply and the regulated power supply to prevent damage to the instrument from the sudden power failure. (It is also possible to add a power-off protector, using an AC contactor plus a double button switch circuit, the rated current is greater than 20A, if there is an online UPS, it may not be equipped).

[Pre:Application of Infrared Carbon and Sulfur Analyzer in Cast Iron Manufacturing]